How

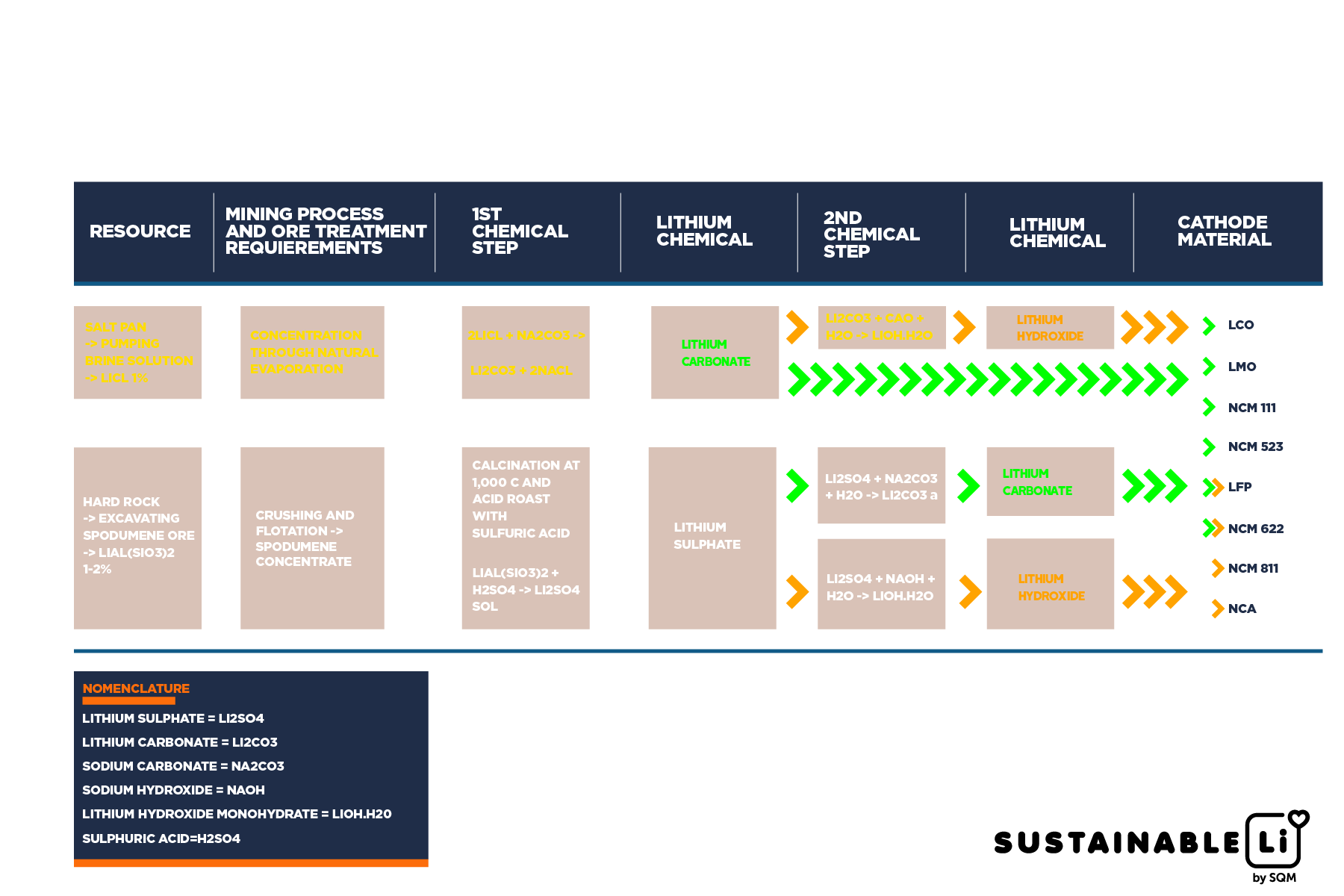

DIFFERENCES BETWEEN THE PRODUCTION OF LITHIUM FROM BRINE AND HARD ROCK

For more than 25 years, SQM has designed and operated a sustainable extraction process for the lithium and potassium ions contained in the brine from the core of the Salar de Atacama. Its responsibility is to protect the natural resources of the area and work on the development of the environment and neighboring communities. For this, it not only has the required environmental approvals, but also works every day to further improve its processes by incorporating cutting-edge technology, measuring and reducing its carbon footprint and optimizing water use.

The company’s commitment is broad: it ranges from protecting the cultural heritage of the communities surrounding the salt flat, to working every day to make production more sustainable.

All SQM operations are highly and constantly regulated by more than 15 different governmental authorities, including Environment, Health and Safety, in accordance with the highest international standards.

SQM was one of the first companies to voluntarily submit an Environmental Impact Study, even before this was a requirement demanded by the authorities. Today, the company has 21 Environmental Qualification Resolutions.

SQM’s sustainability work is favored by the type of extraction that is carried out: it works in basins where brine with lithium chloride and other dissolved salts is concentrated. Drilling is carried out in the salt flat, and the brine is pumped and transferred by pipes to evaporation basins.

Then, in other pools, an evaporation process similar to that at the start is carried out, but under controlled conditions, to achieve a high concentration of lithium and to separate the impurities, which are returned to the salt flat.

Almost no energy is consumed, since the action of the sun and the wind are used, but under strict technical control.

Unlike brine, hard rock lithium mineral deposits involve an intensive use of energy for mining operations, generally open pit, from which the mineral is extracted through a series of steps that involve a greater use of energy and water.

How

SQM has a sustainable process

How

Robust monitoring system

In accordance with current legislation and the environmental commitment, SQM has implemented:

- An extensive hydrogeological monitoring plan with more than 225 hydrogeological monitoring points.

- A flora and fauna monitoring plan through field campaigns, satellite image monitoring, wildlife censuses, limnological studies, etc.

- An Early Warning Plan that regulates brine withdrawals to avoid impacts on the environment. This means that in the face of any negative deviation, the company must reduce its level of extraction immediately, be it water or brine, as appropriate.

How

Online monitoring program open to the community

SQM has an online monitoring program which is open to the community, which can be accessed from the company’s corporate website in the sustainability tab.

These analyses have shown that sensitive objects have maintained their natural behavior, and the levels of the lagoons have remained unchanged as well.

How

Carbon footprint

SQM’s lithium hydroxide production process produces less than 9 kg of CO2 eq/kg with 56% of the emissions from the external raw materials used in the production process. In comparison, the carbon footprint of cobalt is similar and that of gold is ~ 2000X the carbon footprint of SQM (Pöyry 2020, Life Cycle Assessment (LCA) for Lithium Products).

SQM’s carbon footprint is very small, because it uses solar energy to concentrate lithium-rich brines.

Since 2015, SQM has reduced its emissions by more than 20%.

- % emissions

How

Energy use

SQM’s lithium hydroxide production process requires lengthy brine treatments.

The advantages of the process are that, during the evaporation and purification stages, the use of electrical energy is minimal, as more than 95% of all the energy used is solar.

This way of operating limits the environmental impact, because there is very little emission of greenhouse gases.

Every year, SQM uses, on average, 19,345 GWh of solar energy, which represents an equivalent to 25% of the total annual production of electrical energy in Chile.